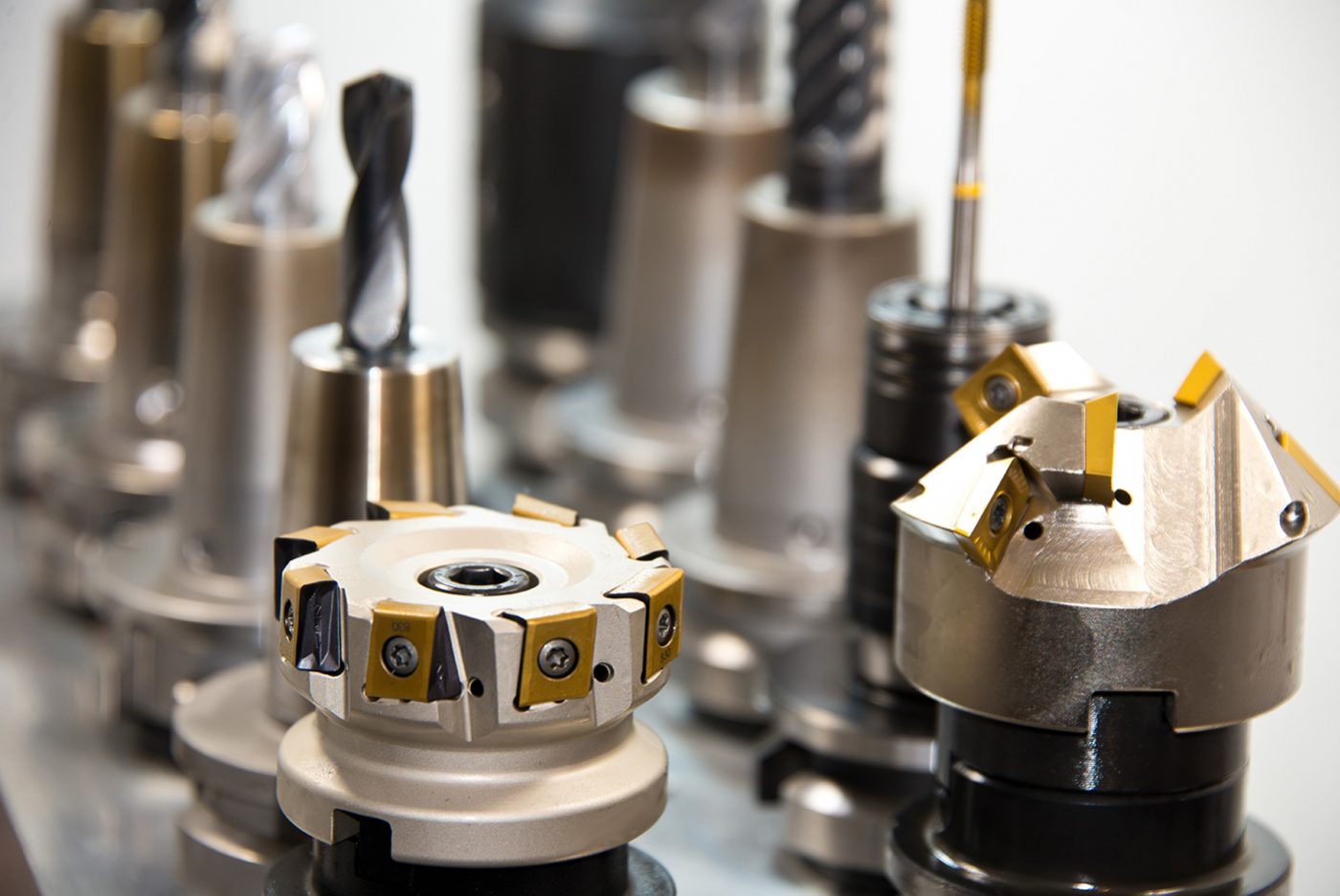

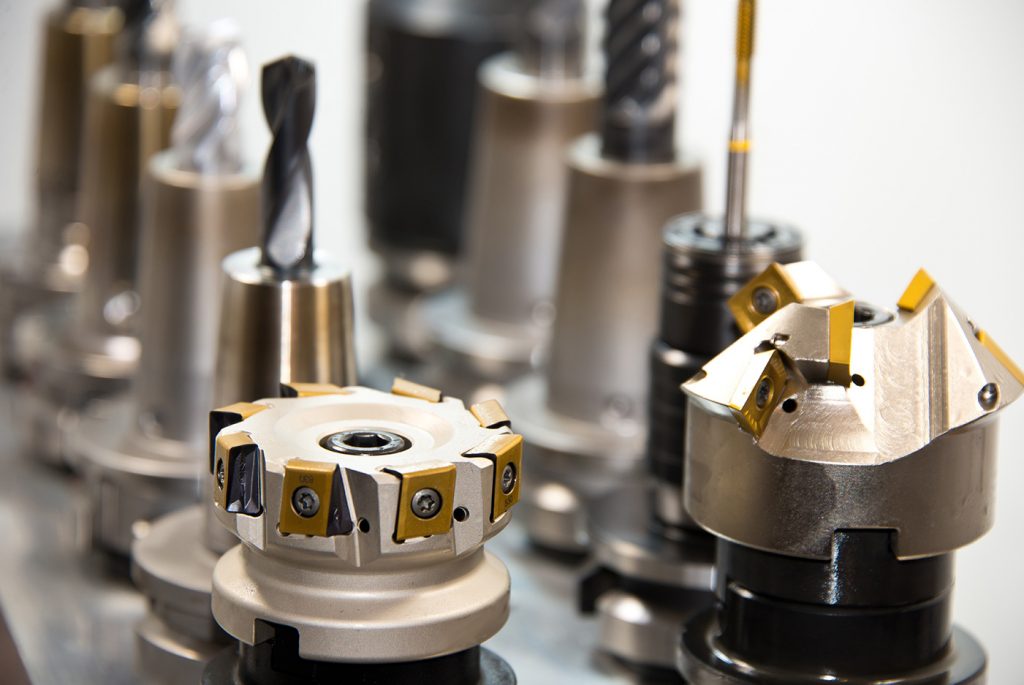

The tooling is a specific department of an industrial plant used for the construction and regulation of equipment for machinery and plants. Proper tooling management allows, in addition to considerable savings on the costs of components subject to wear, to increase the operational efficiency of the factory.

Each equipment is composed of one or more components which can have a long average life (e.g. molds) and be restored with specific maintenance service, or they can be dependent on the level of wear beyond which they must be replaced (e.g. tools). Lacking maintenance or replacement can generate inefficiencies, caused for example by the production of waste, or in the most serious cases, compromise the correct functioning of the system and cause it to break. At the same time, frequent replacement of tools that does not take into account their level of wear can generate waste and higher costs.

The monitoring of the wear state of the systems and the quick detection of faults are two basic elements to obtain a correct maintenance management and consequently save on costs. This allows you to have:

- lower costs for unexpected stops

- lower costs due to lack of quality

- lower energy costs

- improvement in spare parts warehouse management

On the other hand, the unavailability of tools to be mounted in an equipment can cause delays in the delivery of customer orders. Therefore it becomes important to know precisely the need for tools also to avoid situations of obsolescence.

In the past, to ensure that a plant or equipment was used in optimal operating conditions, it was necessary the physical and constant supervision of a specialized worker. The jpiano® MES platform, by monitoring the processes (even in unattended mode) and the state of wear of the equipment and components, is able to detect when it’s necessary to change a tool when one of the following cases occurs:

- negative outcome of the quality control

- process parameters out of range

- tool wear beyond the average life

On each plant or part of the plant or equipment it is possible to install a connector that communicates directly with jpiano®. Through this communication channel it is possible to know the performance and operating conditions, in particular temperatures, couples, signals, number and duration of uses, values ??outside the threshold, presence of alarms and blocks or maintenance needs. This allows the maintenance technician to monitor the products in order to detect any constructive criticalities but also to provide value-added services to its customers such as reporting maintenance needs or suggestions for their best use. The operator can be guided through the visualization on a display of:

- instructions for assembling the equipment

- any parameters to be set on the system

- checklist with any checks to be performed

In the latest generation machinery it is possible to automatically set on the system the operating parameters. Jpiano® also communicates throught smartphone and tablet, on which it is possible to receive information relating to, for example:

- operating conditions of the plants and state of wear of the equipment in real time;

- production progress, automatically and in real time acquiring the data recorded by the sensors present on the machine;

- history of stops, micro-stops and alarms;

- know the exact location of each equipment and its components.