Integrated logistics to be competitive:

how to get it?

Logistics is in charge of the management of material and information flows that cross the business system. Logistics costs occupy a pivotal role in the allocation of total business costs. Consider logistics as a cross-sectional and integrated process with manufacturing and management activities offers new opportunities to improve operational efficiency and to increase the level of service provided to the customer in terms of quality, time and costs. The aim of Logistics is to make available necessary resources (materials, resources or information) when and where requested. According to this point of view, logistics must be involved in planning, organization and control of business activities and it must converse constantly with internal departments, customers, distributors, suppliers, subcontractors and conveyors.

To get a complete and comprehensive vision about what happens along the logistic chain and inside departments, it's necessary to have available appropriate tools to acquire, develop and integrate information coming from multiple sources (administration, production, distribution, purchasing, sales). Furthermore, in presence of unforeseen situation or requiring caution it's necessary to send notifications to interested people so they can intervene quickly. Based on our experience in manufacturing companies, we have identified some features that are particulary requested in the logistic area. They'are shown below.

Delivery planning

Based on the delivery plans agreed with the customer may be necessary to organize transport services (internal or external). Therefore, working backwards from the expected delivery date it's possible to determine various transport characteristics (transporter, type and size transport , date withdrawal). As soon as transport characteristics are identified the date by which the goods to be shipped must be ready for delivery is fixed. Some deliveries can be grouped and included in a single transport order. In case of variations in the order of the customer sales or of unavailability of the goods to be shipped (for example, due to delays in the manufacturing phase) it's necessary a timely intervention for realigning the delivery plan. It's therefore obvious the need to make available to the logistics information about deliveries requested by the customer and about the progress of production orders.

Supply management

The procurement from suppliers, subcontractors, external warehouses, etc. is required based on the material requirements and semi finished available products. As goods are delivered, the MES system carries out some acceptance checks of the material; memorizes their actual entry and prints an identification code for traceability. Similarly it can be useful notify the non-receipt of a specific material caused by a failed delivery or the occurrence of a non-conformity and send an automatic reminder to the supplier. Also in this case it's clear how it's important to integrate purchase processes and those related to the use of the goods ordered.

Shipping management

It's necessary to use suitable IT tools for ensuring efficiency, quality and punctuality of activities related to shipping management. This allows to prepare goods to be shipped in advance, by following an electronic pick list and placing them into the loading area. Furthermore, as soon as the conveyor arrives, it's be possible to manage the loading operations by recording real-time information about packages loaded and check automatically the evasion of all expected items. Through information about loaded goods it's possible to generate automatically the delivery note. All recorded information are immediately available to interested users in monitoring the status of individual shipment progresses.

Location control

First it's necessary to identify and manage the various areas dedicated to logistics operations (loading area, unloading areas, physical location...). For these reason may be required locate and track materials and resources inside the enterprise. These operations can be done by using proven technologies (barcode , RFID tags ... ) or new technologies (beacon). These features allow to ensure that the resources in the company , and related items , are made available when and where requested.

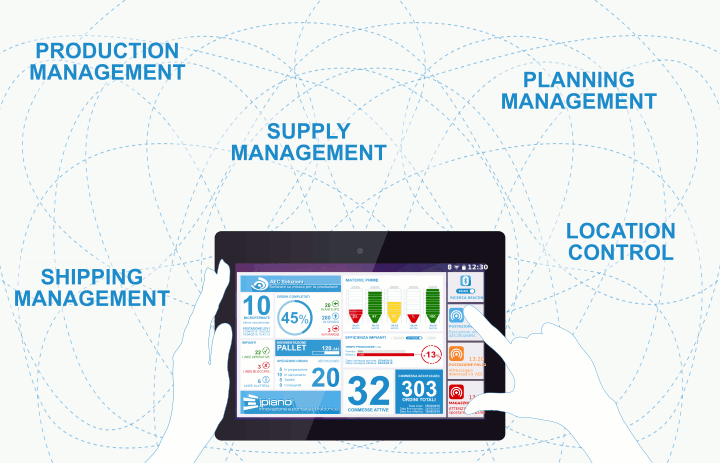

To meet these requirements we have implemented in our MES platform, jpiano®, a module dedicated to the logistics to integrate its management in manufacturing processes.