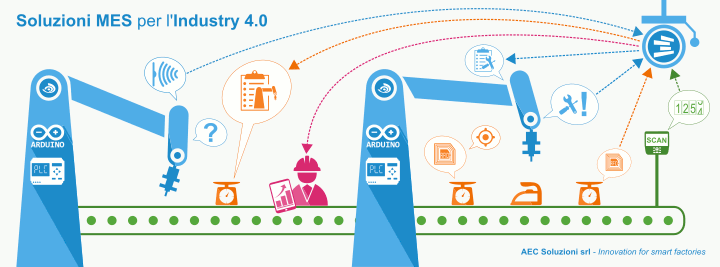

How to digitize manufacturing processes?

For many companies, the purchase of advanced and interconnected workstations for automatizing the production constitutes an unsustainable spending. In many cases this transformation concerns manufacturing plants with obsolete technologies that are most difficult to replace quickly. For these reasons, many companies prefer to focus on the digitization and automation of manufacturing processes.

HOW?

These companies invest in software platforms to structure tailored solutions. This becomes the winning choice to respond in a flexible way to the market demands..

According to recent market researches the level of digitalization present in companies will increase by about 39% in five years. Among the key elements that support the company's digitization, according to Industry 4.0, there are the systems :

- PLM, Product Lifecycle Management;

- ERP, Enterprise Resource Planning;

- MES, Manufacturing Execution System.

Specifically, MES platforms allow to scan, edit and render available more detailed information (including big data) about what's happening inside each department. Such knowledge enables companies to:

- collect, analyze and store data (process and production data) up to date;

- track properly the material and data flows across the business system;

- monitor constantly the daily consumption of raw materials and inventory levels;

- monitor the progress of orders and contracts;

- support a more flexible production by optimizing the planning of activities and allocation of resources and operators;

- do performance comparisons between plants based on the measure OEE calculated (combination of availability, efficiency, and quality);

- identify failures, stops and microstops to prevent them and to generate early warnings;

- obtain the necessary information to plan maintenance (predictive maintenance).

To meet the customer needs, AEC Soluzioni designed and developed jpiano®, a new software platform to support processes of planning , production, quality , logistics , maintenance , distribution. Companies obtain a transparent traceability with jpiano®: from raw materials to finished products.