JPIANO® MES

The information you need, when needed, at every level of the factory

This innovative MES platform - Manufacturing Execution System - was designed for manufacturing companies that want to be competitive in an increasingly demanding market and that often face an organizational change to do so.

Companies must therefore be able to move from a management based on hypotheses and conjectures to a management based on real and objective data. The availability of historical data relating to the progress of the processes is a valid aid for:

- get more visibility of what happens in the individual departments

- have real-time control of key information to monitor industrial costs and factory operating efficiency

- identify possible areas for improvement

- intercept or, if possible, prevent drifts and situations of inefficiency.

JPIANO® FLEXIBLE MES SOFTWARE

Its basic architecture consists of a client-server application, completely developed in Java, which allows it to easily adapt to the internal changes of the same production reality and to the different business realities operating for example in the sectors:

JPIANO® MODULAR AND SCALABLE MES SOFTWARE

Considering the heterogeneity of processes involved, it turned out to be necessary to conceive jpiano® as a modular platform where the individual modules, which can be perfectly integrated with each other, have highly parameterizable functionalities based on the specific needs of each customer. This modular and scalable MES platform allows you to manage the entire life cycle of a job through a single tool.

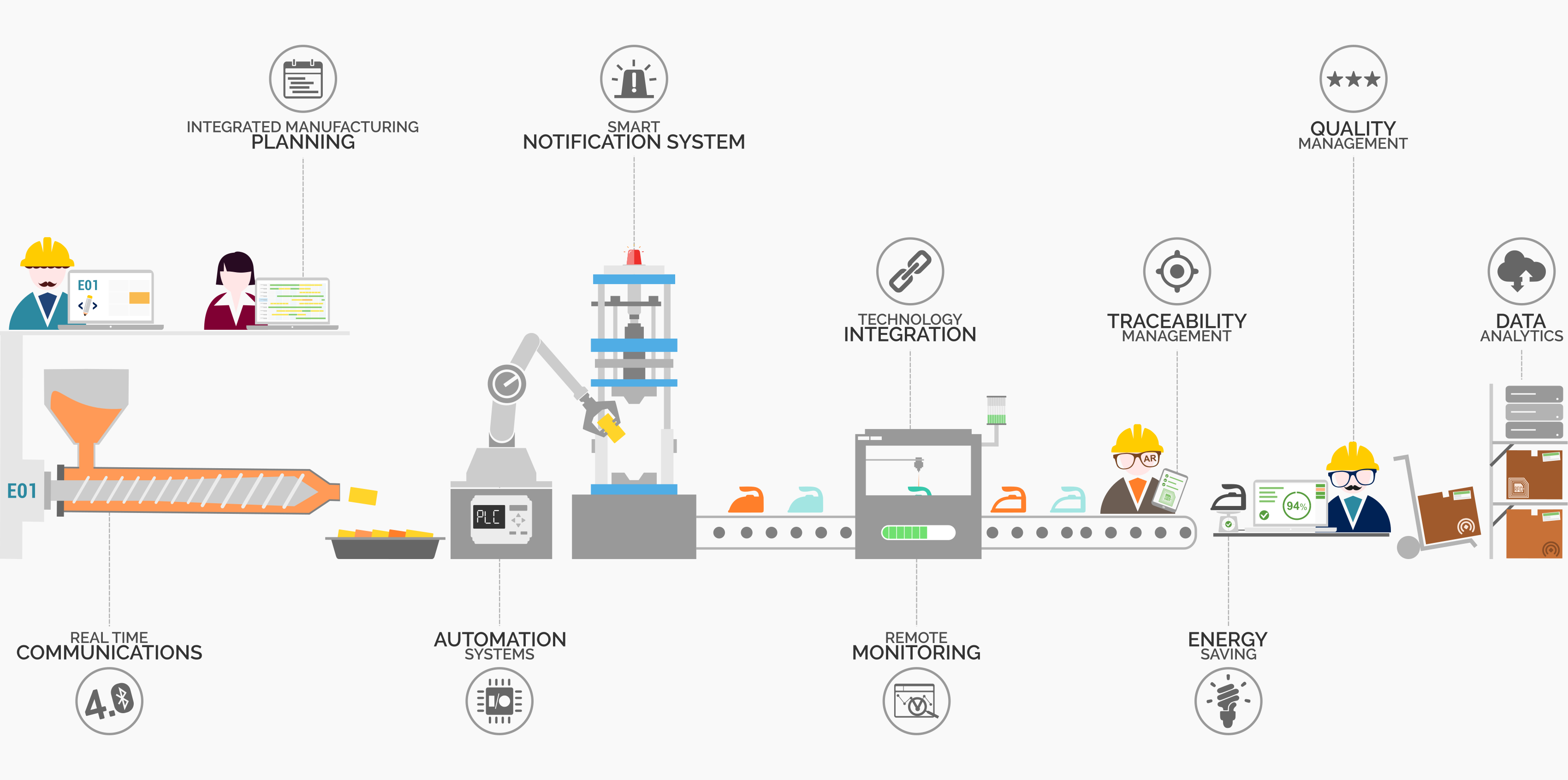

Production 4.0 functions

Modules characterized by specific features to allow companies to switch to

Industry 4.0

- Creation of a virtual company model with structure in terms of departments, plants, centers, headquarters, offices and logistical areas

- Personal cards linked to teams, skills and calendars

- Cards, drawings, instructions, certificates, images, multimedia objects that can be linked with products, semi-finished products, raw materials, equipment, containers and measuring instruments

- Technical data (cycles, BOM and associated resources) directly managed inside jpiano® or captured from external PLM

- Integration with plants, robots, measuring machines and instruments, sensor networks, cyber-physical objects, silos and accessory plants

- Compatibility with specific IoT communication protocols (MQTT and CoAP)

- Integration of devices and sensor networks with low energy consumption and local intelligence for the traceability and monitoring of materials, equipment, containers and plants

- Possibile functions:

- locationing, identification and detection of order progress and environmental conditions

- acquisition of production data, alarms and fault/block reports

- use of mobile and wearable devices such as smartwatches to interact with the jpiano® MES system

- Stock, batch, serial number, object and order management

- Collection of set-up, start-up, loading, unloading, production, waiting, stop and micro-stop (with related reasons) time

- Count of produced, suspended and discarded quantities

- Management of improvement notes, handover and shift change information

- Recipe submit in real time with needed settings for the machine functioning

- Process data acquisition (pressures, temperatures, torques, currents, speeds)

- Alarms and blocks acquisition with warning generation in case of failure or preset conditions

- Data acquisition for traceability, replace and tool wear

- Integration of MES functions within compatible machine control panel

- Availability of connectors with most popular PLC/CNC e.g. Siemens®, Fanuc®, Omron®, Mitsubishi®, Codesys®

- Support for Euromap protocol. Development of specific connectors to OPC-UA, proprietary databases, file systems, RESTful web services and IIoT cloud platforms

- Monitoring of machine/plant status (set-up, start-up, working, waiting for worker, blocking, maintenance) and process parameters

- Information about activities in progress on each plant, in queue and about previous activities (orders, quantity, progress status, scraps)

- Automatic generation of notifications and alarms for events that requiring attention

- Detection of changes to the recipe made directly on machines

- Performance indicators (KPIs) and statistics for measuring operational efficiency

MES Core functions

Modules characterized by functionalities that can be integrated with those of Industry 4.0 and which allow the expansion of production control.

- Definition of new orders (even multi-level) or import from external applications

- Activities programming and their representation on Gantt charts

- Automatic generation of activity plan (purchase, production and service orders) for each component of the order in the various phases (design, tooling, production)

- Real time progress visualization and final accounting of performed activities

- Planning and scheduling of activities at finite capacity with real-time updating of the production plan based on machine information

- Planning takes into consideration expected dates of material receiving and constraints linked to the transport plans

- Evaluation of material and resource requirements (MRP) and generation of purchase proposals, production and equipment orders

- Allocation of operator activities based on required skills and workloads

- Control plans for acceptance, workstation, internal and/or external laboratory

- Generation of control sessions according to customer-defined sampling policies

- Real time integration with machines and measuring instruments

- Issue and printing of conformity certificates of the order

- Automatic generation and non-compliance management

- Generation of non-compliance reports

- Incoming materials registration and assignment of identification code UDC, Loading Unit

- Location survey and complete traceability of the processing from raw material to finished product

- Order and material tracking starting from a specific entry lot and identification of used raw material lots starting from a finished product batch

- Integration with identification systems such as barcodes, RFID tags, NFC tags, magnetic badges, beacons and IoT devices

- Management of multi-material containers (trolleys, pallets, silos) and multi-warehouse structures with logistics area divisions

- Real time check material availability and periodic inventory execution

- Use different devices for operability such as RF terminals, HMI or PC workstations, mobile devices

- Shipments scheduling for single destination or multiple destinations

- Transporter registry and transporter association for delivery points

- Logistics planning integrated with production planning

- Transport order generation and automatic issue of collection order to the supplier

- Management of activities related to shipping (picking, loading, sending)

ADVANTAGES OF JPIANO® MES SOFTWARE

Our solutions, based on jpiano®, allow you to:

manage planning, production and logistics through

A SINGLE MES SOFTWARE TOOL

valorize BIG DATA of production/process

along INDUSTRY 4.0 perspective

improve operability and traceability

via IoT devices

put into communication company resources

to obtain a 360° INTEGRATION

create TAILOR-MADE PROJECTS

for medium-large companies

enhance all company resources becoming

INDUSTRY 4.0 COMPLIANT

achieve a VISUAL MANAGEMENT system

to have all the processes under control

guarantee a high level of automation by maintaining

MAN AT THE CENTER OF THE PROCESS

create a SMART NOTIFICATION SYSTEM

to reduce stops and production blocks